April 27, 2023

The common goal to address the global issue of plastic pollution has led to a series of policies, regulations, legislation, and industry initiatives, which focus on:

- reducing problematic & unnecessary single-use plastics,

- increasing collection and recycling rates,

- re-designing packaging to make them fit for reuse, recycling, or composting, and

- increasing recycled content in plastic packaging.

Traditionally, the demand for recycled plastics has been weak but now it is on the rise, thanks to the recycled content targets set by regulatory bodies and the voluntary commitments made by global brands and industry leaders.

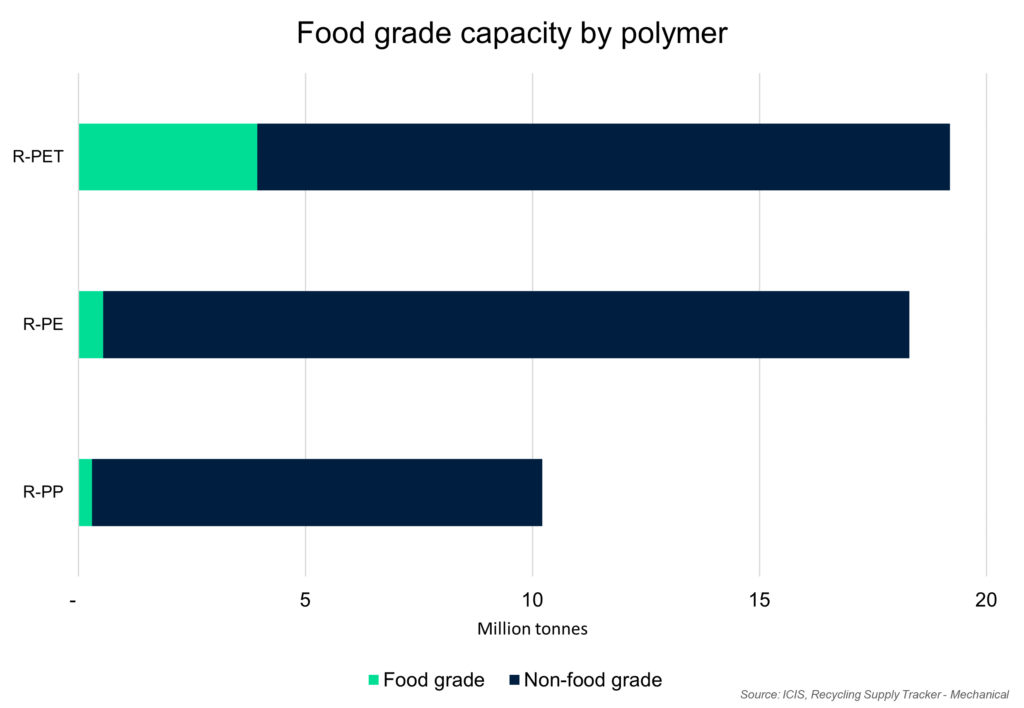

Such targets, together with new investments, innovation and technological developments can potentially lower our dependency on virgin plastics and enable a circular and resource-efficient plastics economy. However, volatile oil prices and a lack of reliable, high-volume supply of recycled materials with consistent quality standards act as roadblocks for the adoption of recycled plastics. And when it comes to the use of recycled plastics in food packaging applications, the possible presence of contaminants from post-consumer plastic waste makes meeting safety requirements more complex, especially with mechanical recycling. As per a recent report, food-grade resins currently represent only 10% of the global annual capacity of recycled polymers of over 45 million tonnes, according to ICIS Mechanical Recycling Supply Tracker. The research includes recycled polyethylene terephthalate (R-PET), recycled polyethylene (R-PE), and recycled polypropylene (R-PP). 4

The adoption of advanced recycling technologies complimentary to mechanical recycling processes will, therefore, be critical in securing the required supply of food-grade recycled plastics and ensuring plastic circularity.

Additionally, we need:

- better collection, sorting and integration of recycling activities into the plastics value chain

- harmonised science-based regulations & certifications

To meet the minimum recycled content requirements across all plastic packaging in the coming years, cross-industry partnerships and strong commitments from brands & key industry players will play a major role.

A leading example is that of Nestlé, which has set in motion several initiatives to deliver on its goal of achieving net-zero emissions by 2050. Within its detailed climate roadmap, the company is actively driving the shift towards innovative sustainable packaging solutions. It has committed to:

- make 100% of its packaging recyclable or reusable by 2025

- reduce its use of virgin plastic in packaging by one third by 2025

- source up to 2 million metric tonnes of food-grade recycled plastics and allocating more than CHF 1.5 billion to pay a premium for these materials between 2020 and 2025

Nestlé has also launched a CHF 250 million sustainable packaging venture fund to invest in start-up companies focusing on packaging innovation (new materials, refill systems, recycling solutions, etc.). This is in addition to the research and development of packaging innovation drive by the Nestlé Institute of Packaging Sciences. 5

Bringing sustainable food packaging solutions to market

Delivering on its commitment to bringing sustainable solutions to the market, Nestlé will be introducing new ISCC PLUS certified packaging for one of its leading brands—Nesquik, which is made with up to 50% recycled plastic for the UK market. The advanced recycled content of this packaging is allocated using the ISCC mass balance approach, a certified chain of custody model, which helps track and measure recycled inputs & outputs. In a complex production process, where sustainable and fossil-based feedstocks look identical and are mixed, the sustainable content is tracked & documented accurately using mass balance book keeping system. This enables the determination of the percentage of recycled content in the final product.

High-density polyethylene (HDPE) is the material of choice for the body of the canister. The new packaging, to be launched in the UK and France, is made with food-grade recycled HDPE, allowing Nestlé to significantly reduce the use of virgin HDPE.

The production site, Nestlé’s Pontarlier Factory in France has received the ISCC PLUS certification following an audit conducted by Bureau Veritas (an independent third-party certification body) and the new Nesquik packs (250g, 300g, 500g, and 600g) featuring the ISCC PLUS logo will soon be launched in the UK and France.

ISCC is committed to supporting the shift towards a circular economy and is proud to support brands like Nesquik in their endeavour to bring sustainable packaging solutions to market. “We continue to double down our efforts in tackling the issue of packaging waste by accelerating the development of innovative sustainable packaging solutions as well as working with others to advance circular economy,” said Gylane Aboulkheir, Marketing Manager Dairy, Nestlé France. “The introduction of Nesquik packaging made with ISCC PLUS certified food-grade recycled plastic is a step further towards of meeting our target to reduce our use of virgin plastics by one third by 2025.”

References:

- https://ellenmacarthurfoundation.org/topics/plastics/overview

- https://plasticseurope.org/sustainability/circularity/recycling/mandatory-recycled-content/

- https://www.americanchemistry.com/chemistry-in-america/news-trends/blog-post/2021/30-by-30

- https://interplasinsights.com/plastic-industry-insights/fda-and-efsa-food-grade-recycled-resins-are-required-to-reac/

- https://www.nestle.com/media/pressreleases/allpressreleases/nestle-market-food-grade-recycled-plastics-launch-fund-packaging-innovation